Offshore wind turbines foundations

How are offshore wind turbines anchored at sea?

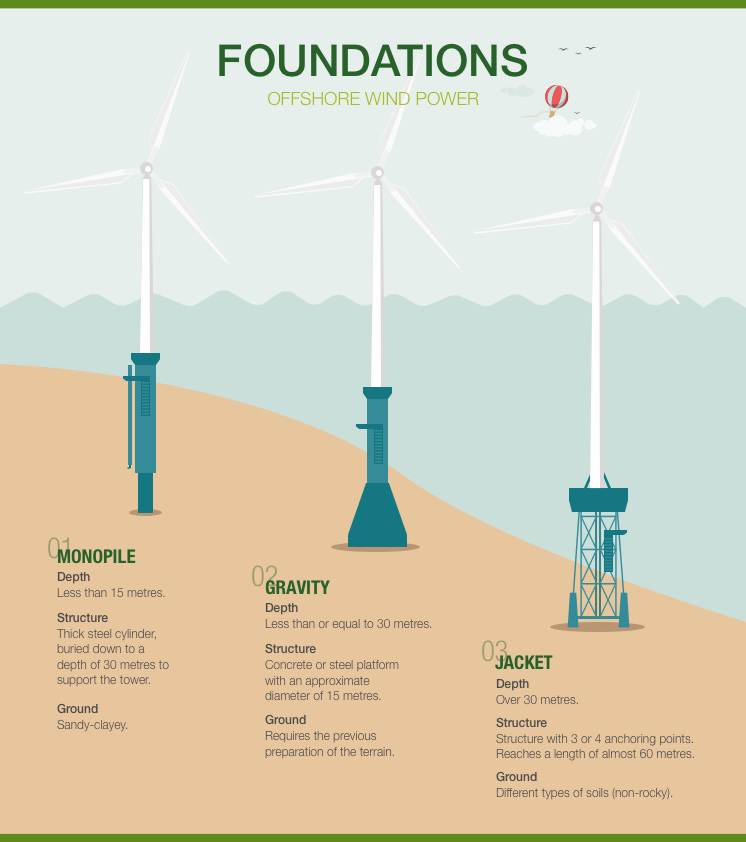

In offshore wind farms, wind turbines are elevated over the sea level with different types of foundations, depending on the depth.

Offshore wind power projects are used to exploit the potential of wind in open seas, where wind blows stronger than on land. However, the installation of offshore wind farms is a complex task. The biggest problem lies in elevating wind turbines and substations above the sea level and anchoring them to the sea bed.

The history of offshore wind has been marked by continuous innovation. Now there are different types of foundations, according to the depth at which the wind turbine will be installed. Therefore, for example, in installations at depths below 15 metres, monopiles are used; these are quite simple structures, made up of a thick steel cylinder that is anchored directly to the sea bed. They are buried under the sea bed up to 30 metres to support the tower.

In the case of offshore wind farms that need to erect the wind turbines 30 metres over the sea level, clear from the action of waves, the gravity foundation system is usually used, which involves using a large concrete or steel platform with a diameter of approximately 15 metres and a weight of approximately 1,000 tons.

More complex support and anchoring structures are required at depths below 30 to 35 metres. In most cases, installation companies use jackets, foundations with a lattice framework that feature three or four sea bed anchoring points, which increases the levels of safety when anchoring the towers. The top of the jackets features a transition piece that is connected to the turbine shaft, while the legs (three or four, according to the engineering design) are anchored to the sea bed with piles.

Discover the main characteristics of the foundations that are most commonly used for the installation of an offshore wind farm: External link, opens in new window.

SEE INFOGRAPHIC: Foundations, offshore wind power [PDF] External link, opens in new window.

SEE INFOGRAPHIC: Foundations, offshore wind power [PDF] External link, opens in new window.

Jackets are the foundations used by Iberdrola in the Wikinger (Germany), East Anglia ONE (United Kingdom) and Saint-Brieuc (France) offshore wind farms.

- In the German wind farm, the jackets have four legs, with a 59-metre length and 625-ton weight.

- Similarly, the wind turbines of the East Anglia ONE offshore wind farm are supported by three legs — even through the wind turbines are larger —, an engineering challenge that allows the company to save costs and accelerate the manufacturing of structures.

- Finally, the jackets will be installed in the Saint-Brieuc offshore wind farm because it is an appropriate technical solution for the seabed conditions in the Saint-Brieuc Bay and jackets were a type of foundation selected by fishing organisations.

Construction of an offshore wind plant

Everything about offshore wind farm construction.

Where to install offshore wind farms

How is the location of offshore wind farms chosen?

Evolution of wind energy in Europe

The European wind market has grown strongly over the last 25 years. Find out more.

Floating offshore wind

A milestone to boost renewables through innovation.

In both cases, the foundations were manufactured by Spanish companies: they have been manufactured by Navantia and Windar at their Ferrol and Avilés facilities, respectively. The manufacturing of jackets has generated a very positive economic impact in these areas. A representative piece of information: in the Galician facilities, the work for the Wikinger offshore wind farm has translated into the creation of 2,000 jobs (direct and indirect jobs).