Industrial Internet of Things (IIOT)

What is IIoT? Discover the Industrial Internet of Things

According to Oxford Economics data, the Industrial Internet of Things (IIoT) can impact industries that account for 62 % of GDP in the G20 countries. Some of these include manufacturing, energy and food. The application of IIoT in industry promises to become the biggest driver of productivity and innovation in the next decade.

There are currently 4.6 billion people connected to the internet on the planet, but they are not alone: it is estimated that there are 30 billion devices connected to the network that interact without human intervention, forming the so-called Internet of Things (IoT). Often, this technology is presented using examples such as a refrigerator that places an order with the supermarket when the milk has run out. However, most of its applications are in industry and the Industrial Internet of Things (IIoT) will be a key part of the Fourth Industrial Revolution.

WHAT IS THE INDUSTRIAL INTERNET OF THINGS (IIOT). DIFFERENCES WITH THE IOT

The Industrial Internet of Things (IIoT) is the collection of sensors, instruments and autonomous devices connected through the internet to industrial applications. This network makes it possible to gather data, carry out analyses and optimise production, increasing the efficiency and reducing the costs of the manufacturing process and the provision of services. Industrial applications are complete technological ecosystems that connect devices and these with the people who manage the processes in assembly lines, logistics and large-scale distribution.

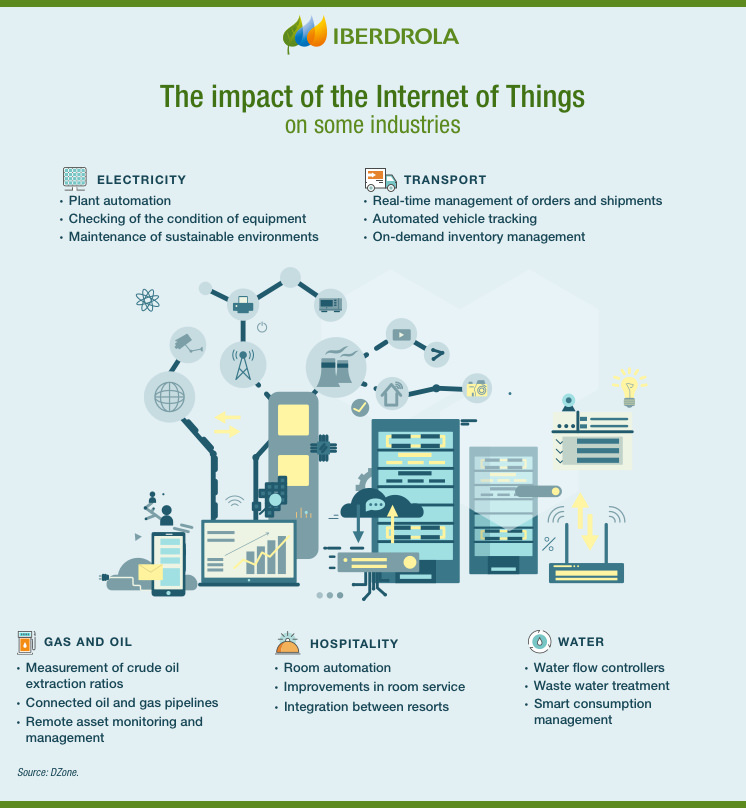

Current IIoT applications are primarily concentrated in manufacturing, transport and energy, with an investment of over 300 billion dollars worldwide in 2019 which is expected to double by 2025. In the immediate future it is expected that the adoption of the IIoT will result in the implementation of more industrial robots, such as cobots, warehouse and transport control systems, and predictive maintenance systems.

The difference between the Internet of Things (IoT) and its industrial version (IIoT) is that while IoT focuses on services for consumers, IIoT focuses on increasing safety and efficiency at production sites. For example, consumer solutions have focused on smart devices for the home, from virtual assistants to temperature sensors or security systems, or for people, such as wearables that monitor health.

CHARACTERISTICS OF THE INDUSTRIAL INTERNET OF THINGS (IIOT)

Not all systems can be classified as IIoT. In general, they need to be networked systems that generate data for analysis and produce concrete actions. The operation of IIoT systems is based on a layered structure:

- Devices. The visible part of the system is the devices: sensors, GPS locators, machines, among others.

- Network. Above this is the connectivity layer, i.e. the network that is established between these devices and the servers through cloud storage or edge computing.

- Services. These are computer applications that analyse the data collected and process them to offer a specific service.

- Content. This is the interface with the human operator, which can be a computer, a tablet or even devices such as virtual reality or augmented reality glasses.

APPLICATIONS AND SOLUTIONS OF THE INDUSTRIAL INTERNET OF THINGS (IIOT)

The applications of the Internet of Things in industry are varied, but below we review some of the most relevant:

Use of autonomous vehicles

The transport of components to the plant or products to the warehouse can be done by autonomous vehicles that are able to move from one side of the factory to the other by detecting obstacles.

Optimisation of machine performance

An inactive machine represents a loss of revenue. Thanks to sensors and data processing, it is possible to optimise machine utilisation time inside a manufacturing plant.

Reduction of human errors

Human operators will continue to be essential for many tasks, but the tools they use will be connected to the system to save time and avoid errors.

Improvement in logistics and distribution

Stored products incorporate sensors that provide real-time data on their location and even on their temperature and surrounding conditions which will be particularly useful during, for example, the distribution of the COVID-19 vaccine.

Decrease in the number of accidents

Wearables, such as goggles, bracelets and gloves, allow data to be collected from the operator wearing them. Examples of this data range from their location or proximity to machines, to their pulse, temperature and blood pressure, thereby reducing the possibility of accidents.

BENEFITS OF THE INDUSTRIAL INTERNET OF THINGS (IIOT)

The IIoT brings many advantages to companies, and here are some of the main ones according to the consulting firm Morgan Stanley:

- It increases efficiency and productivity.

- It creates new business opportunities.

- It reduces the cost of assets during their life cycle.

- It enhances the safety of workers.

- It drives the product innovation process.

- It improves the understanding of consumer demands.

TECHNOLOGIES RELATED TO THE INDUSTRIAL INTERNET OF THINGS (IIOT)

The present and future implementation of the IIoT is closely linked to the most recent technological developments: